Sake Classifications and Polishing Ratio

Rice Polishing Ratio

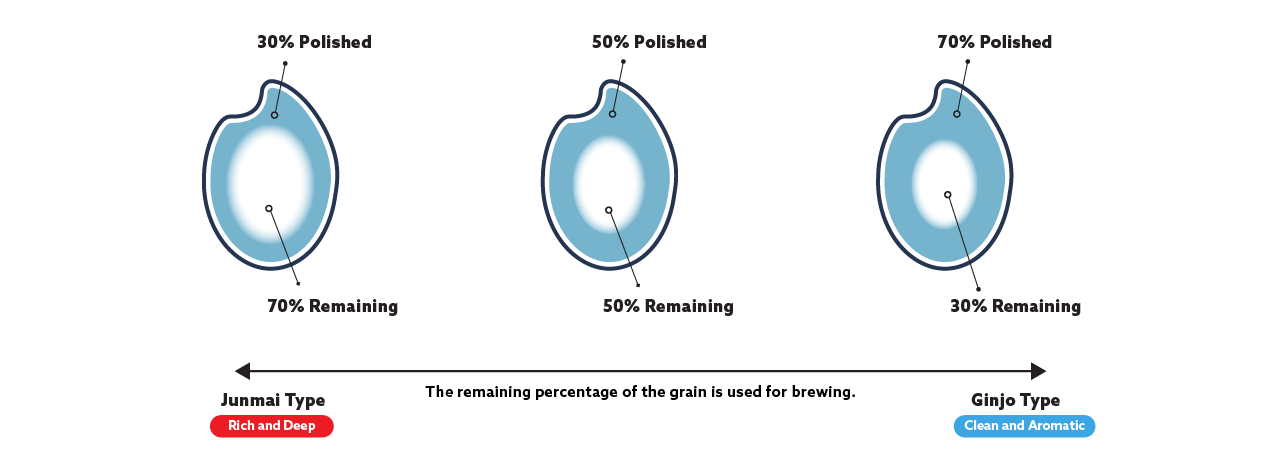

Sake is made with rice that has been polished or milled down. It is important to understand that all rice is brown prior to removal of the husk.

The husk and outer portion of the kernel contain more protein and fats than the inner portion of the grain. These two components can produce umami and some undesirable aromas and undesirable flavors in the sake.

The rice polishing ration is the percentage of the rice that remains after the husk (outer portion) of the brown rice is polished off.

It usually takes 2 to 3 days to polish rice down to less than half its original size (50% rice polish ratio). As a result, sake made with rice that has been highly milled (much of the rice has been polished off) is usually more expensive than sake that has been made using less polished rice.

However, this does not always mean that sake made by highly milled rice is of better quality than sake made by rice that has been milled less. The sake made with the more highly polished rice is certainly cleaner and more refined.

Ultra Low Polishing Ratio

How low can you go?

It turns out the answer is very low. As you may know from our “classifications”, if a brewery wants to make a Daiginjo grade sake, they must polish the rice down to at least 50% remaining. If you have been reusing the sake aisle at a local retailer or searching through online retailer’s selections, you will notice many are in fact polished to a greater degree with a ratio of around 45% to 35%, think Hakkaisan 45 Daiginjo, Asahi Brewery, Tsugu, and the like.

In the recent years, an increasing number of breweries are experimenting with even lower polishing ratios, creating rare and ultra premium sake. What once would have seemed impossible, we are now seeing single digit polish ratios!

Before the invention of the rice polishing machine, the polishing ratios in the teens let alone single digits were unimaginable. The earliest form of rice milling was powered by man. For ashibumi semai, milling was driven by the human foot. And even with the invention of water-powered mills rice polishing was brought down to 90% remaining.

Photo by takarausa.com

Even with the latest technologies, rice milling is both slow and arduous. Great care must be taken to not crack or break any of the rice grains. There are handful of breweries that are currently making sake with seimaibuai in these single digits.

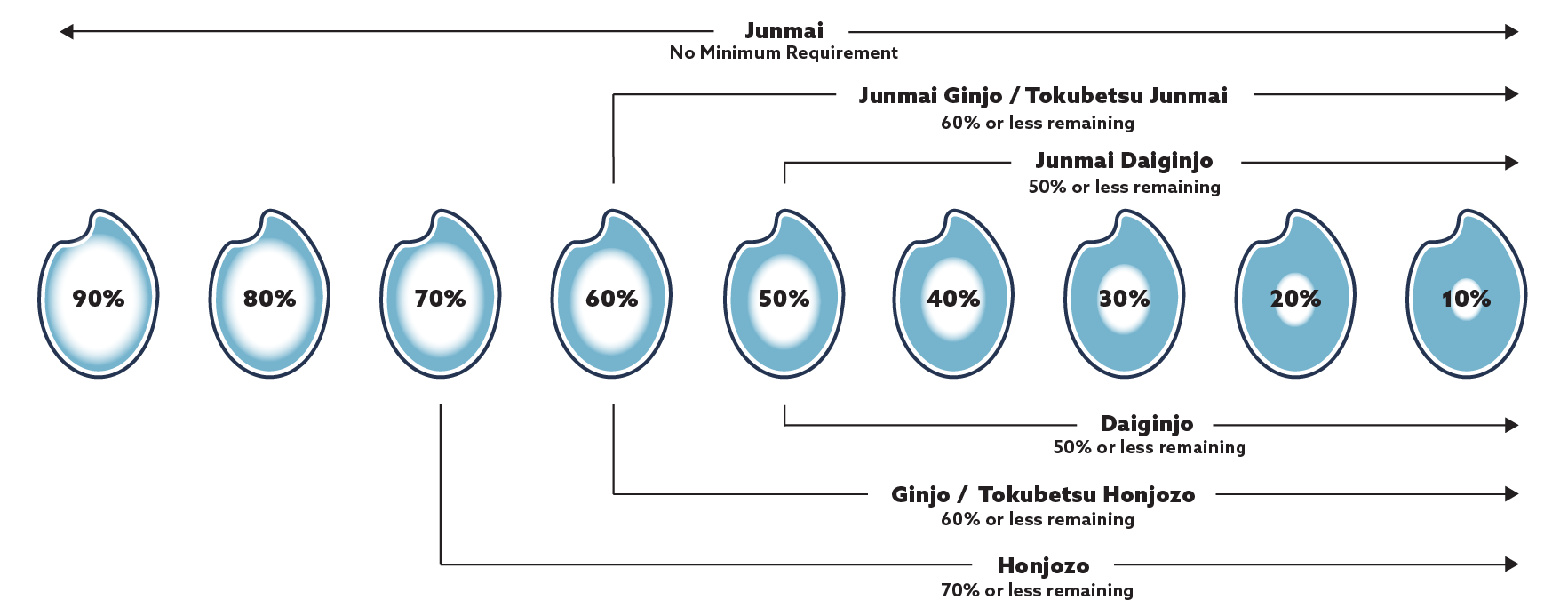

Sakes are classified in 8 different categories based on the ingredients and the rice polishing ratio. Each category reflects a specific characteristic fragrance and taste, so you can use a category name in searching for your favorite sake.

Distilled alcohol, typically made from the fermentation of sugar that is refined from sugarcane, can be added to four types: Daiginjo, Ginjo, Tokubetsu (Special), and Honjozo. The quantity of distilled alcohol has a direct effect on the fragrance of the sake as well as its shelf life. The distilled alcohol that can be added must be less than 10% of the total weight of the polished rice. This is one of the essential regulations involved in the process of making sake.

Sake Classifications

NO ALCOHOL ADDED

ALCOHOL ADDED

Flavors By Category

Daiginjo

Lightest, most ethereal, with floral, tropical fruit and often exotic spice notes. Intensity of aroma can vary, but these sake are among the most floral and fruity.

Ginjo

All Ginjo and Daiginjo sake have aromas of fruit and flowers. Sake labeled simply Ginjo or Junmai Ginjo possess a spectrum of flavors ranging from floral and fruit notes to delicate rice, mineral or earth notes.

Junmai/Honjozo

The sake with lower polishing and more earthy, ricey, and mineral notes. Many of these sake benefit from gentle warming!

Tokubetsu

Tokubetsu means “special”. Tokubetsu sake have wide ranging flavors often relating to special production techniques, rice or unique flavor profiles. Typically, great values, as they often could be classified as higher grade. Tokubetsu sake are often more complex, with less fruit and floral character.